Description

Manak Pharmed — Exclusive Representative of Hanyang

Leading Manufacturer of Cleanroom Garments

Cleanroom Garments

Details

Types of Cleanroom Garments

Disposable and Reusable Cleanroom Garments

Cleanroom Apparel for Pharmaceutical Companies (General & Hazardous Areas)

Cleanroom Clothing for Hospitals

Cleanroom Garments for Medical Device Manufacturers

Cleanroom garments are used in industries such as pharmaceuticals, electronics, biotechnology, and hospitals, where contamination control is critical.

Key Features of Cleanroom Clothing

Antistatic / ESD Control Fabric

Autoclavable and Machine Washable

Non-linting and Particle-free Material

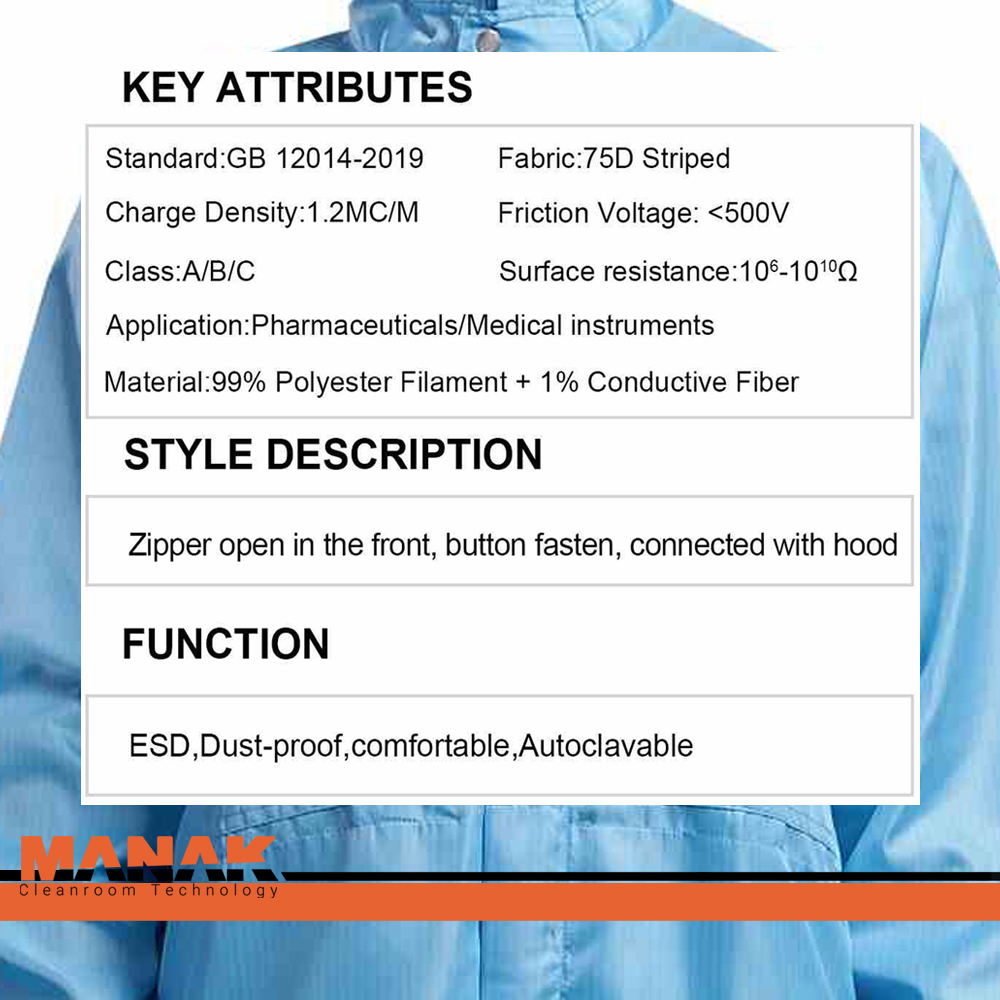

Material

Fabric Composition: 99% Polyester + 1% Conductive Fiber

Stainless Steel Zipper

Size & Color

Available Sizes: Small, Medium, Large

Colors: White, Blue, Pink

Download the Cleanroom Garment Catalog (PDF)

Cleanroom Apparel Range (by Manak Pharmed)

Manak Pharmed supplies a complete range of Hanyang cleanroom garments including:

Cleanroom Gown: One-piece or two-piece design with sealed seams and ESD protection.

Cleanroom Mask: Prevents the spread of respiratory particles.

Cleanroom Cap / Hood: Full hair and head coverage (Bouffant Cap or Hood).

Cleanroom Gloves: Powder-free latex or nitrile material.

Cleanroom Boots / Shoe Covers: ESD-safe and non-particulating.

Cleanroom Slippers: ESD-protected, low-particle footwear.

Antistatic (ESD Control) Cleanroom Clothing

Antistatic or ESD-control cleanroom garments are designed to prevent particle emission and protect personnel from electrostatic risks.

These garments are chemically resistant to acids, organic solvents, and high temperatures.

They also prevent electrical discharge damage to sensitive electronic components and reduce ignition risks in environments with solvents or flammable materials.

Additionally, they help prevent particle and microorganism accumulation inside cleanroom zones.

Cleanroom Gowning in Pharmaceutical Manufacturing

Cleanroom garments vary based on product type and cleanroom classification.

Types of Pharmaceutical Cleanroom Garments

Two-piece Garment: Separate top (smock) and bottom (pants).

One-piece Suit: Combined smock and trousers for full coverage.

Coverall Suit: A one-piece suit covering the entire body from head to foot.

Cleanroom Garment Specifications

Fabric:

Must be non-linting, easy to clean, antistatic, and microbe-resistant.

Recommended material: 100% Polyester.

For sterile and injectable product areas, garments must be chemically resistant and autoclavable.

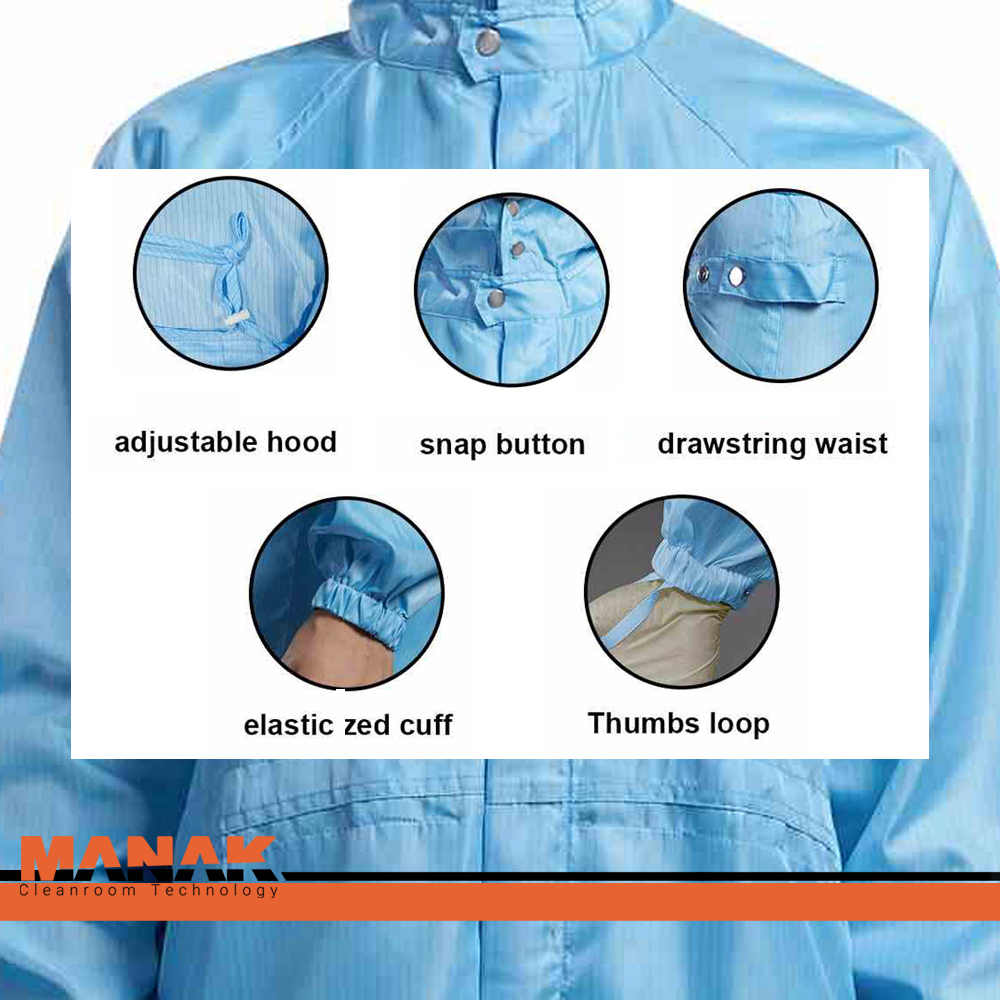

Design:

Unisex one-piece coveralls with adjustable cuffs, no pockets, and front zippers (stainless steel or non-metal).

Designed in accordance with ISO 14644 and EU-GMP requirements, varying by cleanroom class and hazard level.

Cleanroom Garment Classes and Gowning Requirements

Class D Cleanroom: Cap, face mask, cleanroom shoes, and smock.

Class C Cleanroom: One-piece or two-piece garment, plus cap, mask, gloves, and footwear.

Class A/B Cleanroom: Full-body autoclaved, particle-free coverall with integrated hood, sterile gloves, goggles, and ESD boots—covering the entire body to prevent particle emission.

General Requirements (Based on ISO 14644 & EU-GMP)

A) Particle Control

Low Particle Shedding: Non-woven or microfiber fabric compliant with ISO Class 5 or better.

Sealed Seams: Heat-sealed or seamless stitching to prevent leakage.

B) ESD Control (IEC 61340-5-1)

Surface resistance between 10⁶ and 10⁹ ohms.

Required for flammable solvent handling areas.

C) Garment Design

Full Body Coverage: Integrated hood, coverall, gloves, and boots designed for cleanroom compatibility.

EU-GMP Compliance

A) Microbial Contamination Prevention (Annex 1)

Must be sterile, autoclavable, or single-use for Grade A/B environments.

B) Garment Integrity

Tested per EN 13795 Surgical Gown Standards.

Latex-free and powder-free materials only.

C) Operator Comfort & Safety

Breathable, moisture-wicking fabric with low particle emission.

Chemically resistant to alcohols, hydrogen peroxide, and common disinfectants.

Applications of Antistatic Cleanroom Garments

Pharmaceutical Manufacturing Facilities

Research & Quality Control Laboratories

Food Processing Plants

Cosmetics & Hygiene Industries

Electronics & Semiconductor Labs

Chemical and Industrial Workshops

Paint & Coating Areas

Printing and Packaging Industries

Reviews

There are no reviews yet.